6501-6506 Packed Slip Single & Dual Expansion Joints

Information at a Glance

Series

6500 Perma-Pax Slip Expansion Joints

Material

Steel

Size

2-24+ in.

Pressure

≤150 & 300 PSI / 10 & 20 Bar

Motion

24+ in.

Canadian Registration

![]()

This product is registered throughout Canada under

CRN 0D9278.59870YTNADD3

Other Products

Product Description

Series 6500 Perma-Pax Packed Expansion Joints

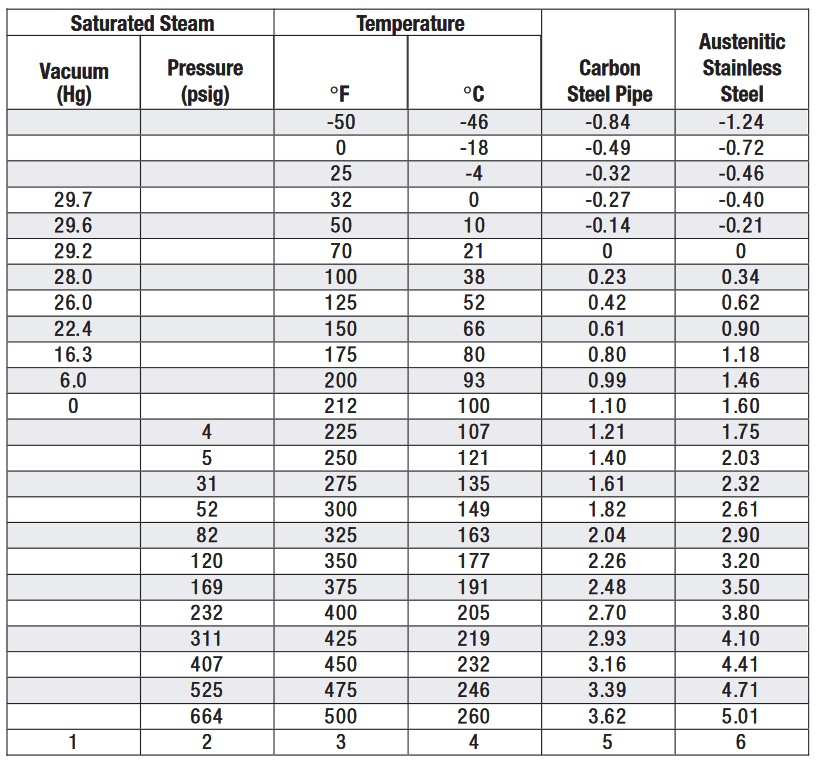

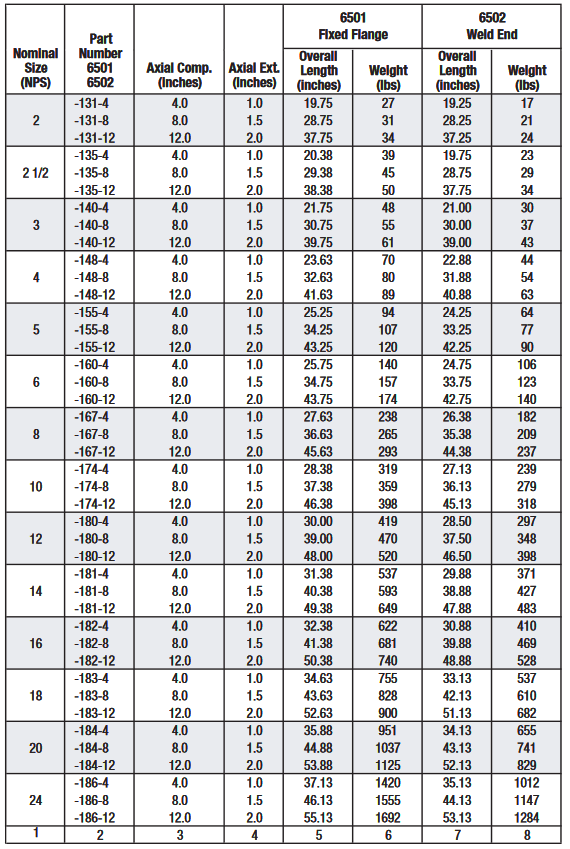

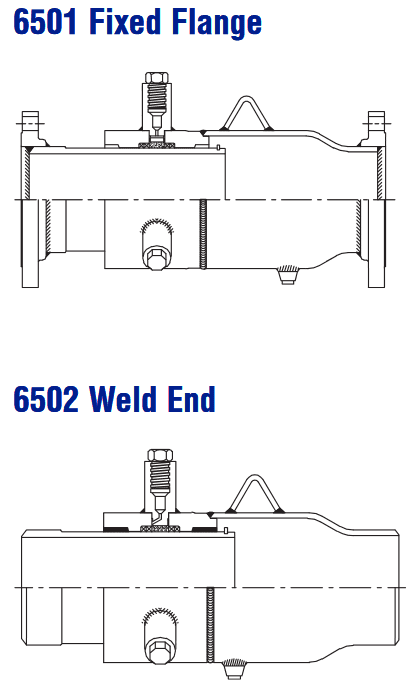

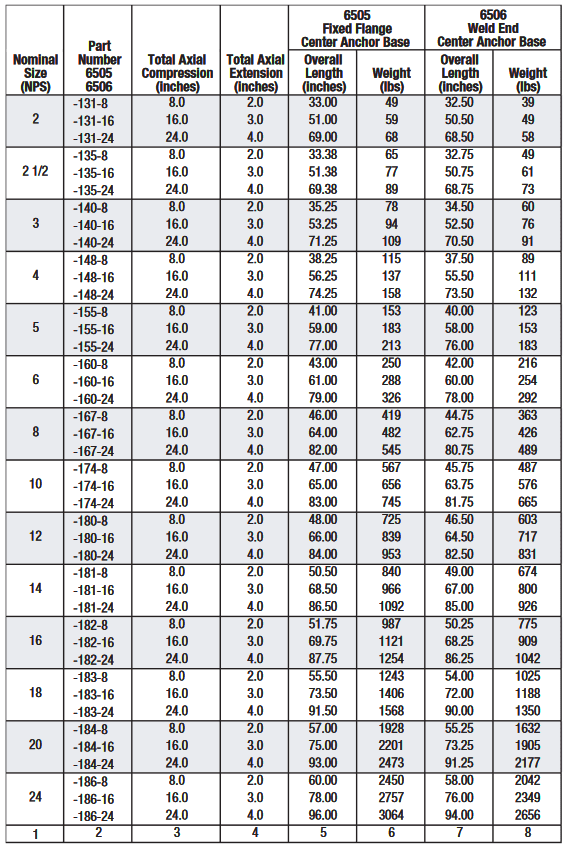

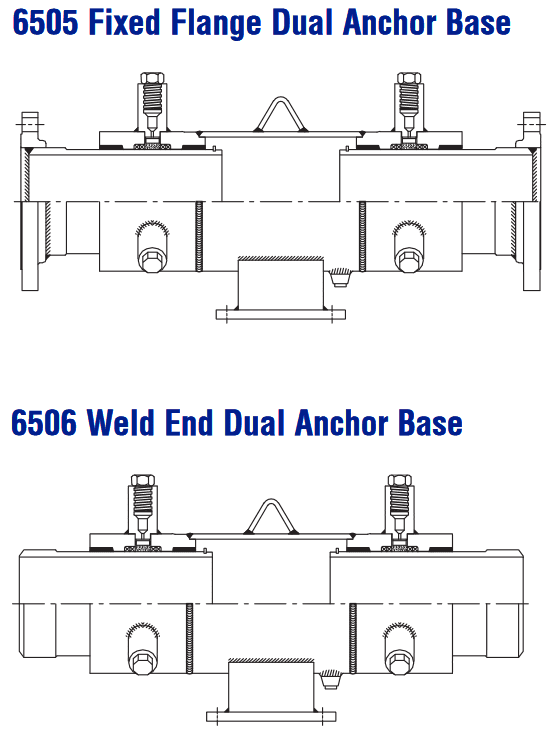

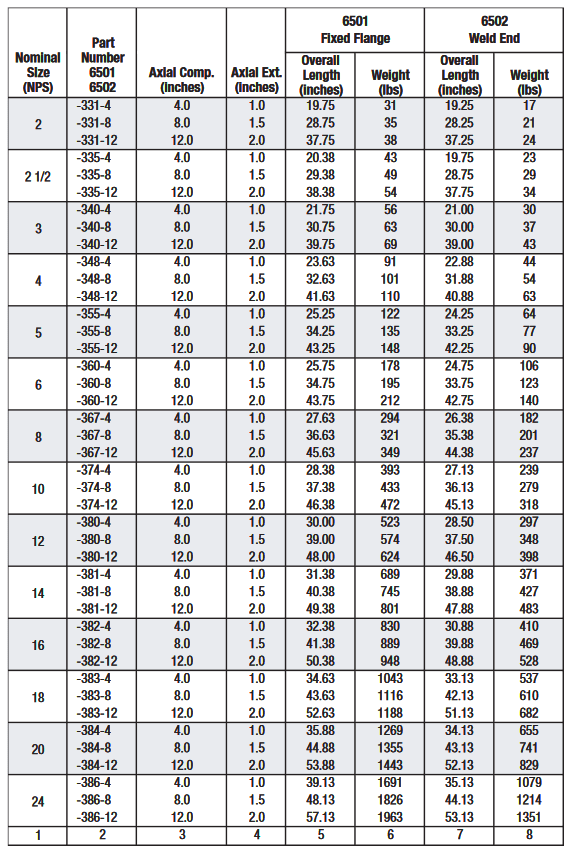

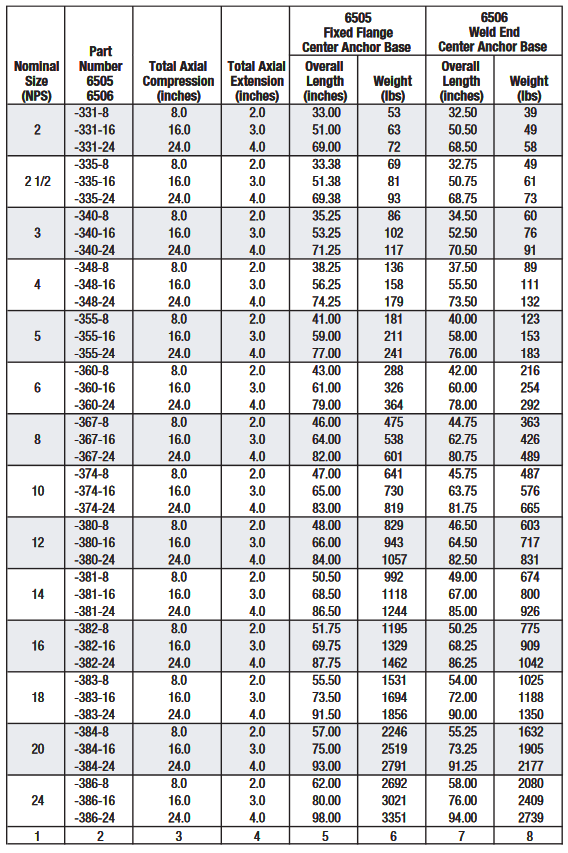

Series 6500 Packed Expansion Joints are designed for installations where the principal movement is axial. Standard single and dual designs are available 2″ through 24″ diameter with travels of 4″, 8″ and 12″ compression for single designs, and 8″, 16″ and 24″ compression for dual designs. Service conditions are 150 and 300 psig to 500°F. Welded and flanged end connections are standard, with grooved ends optional.

Technology & Advantages

Series 6500 expansion joints incorporate design features that are not available from other manufacturers. They include a one piece body which eliminates a circumferential weld, line bored aluminum bronze metal inner and outer guides, and an optimized sealing system consisting of carbon fiber graphite impregnated braided packing combined with Grafoil® Flexible Graphite injected packing.

These features combine to provide a standard product with the lowest seal resistance force available, self lubrication, and precision internal metallic guides. Series 6500 products are available from stock and include a Five year full replacement warranty.

Common Applications

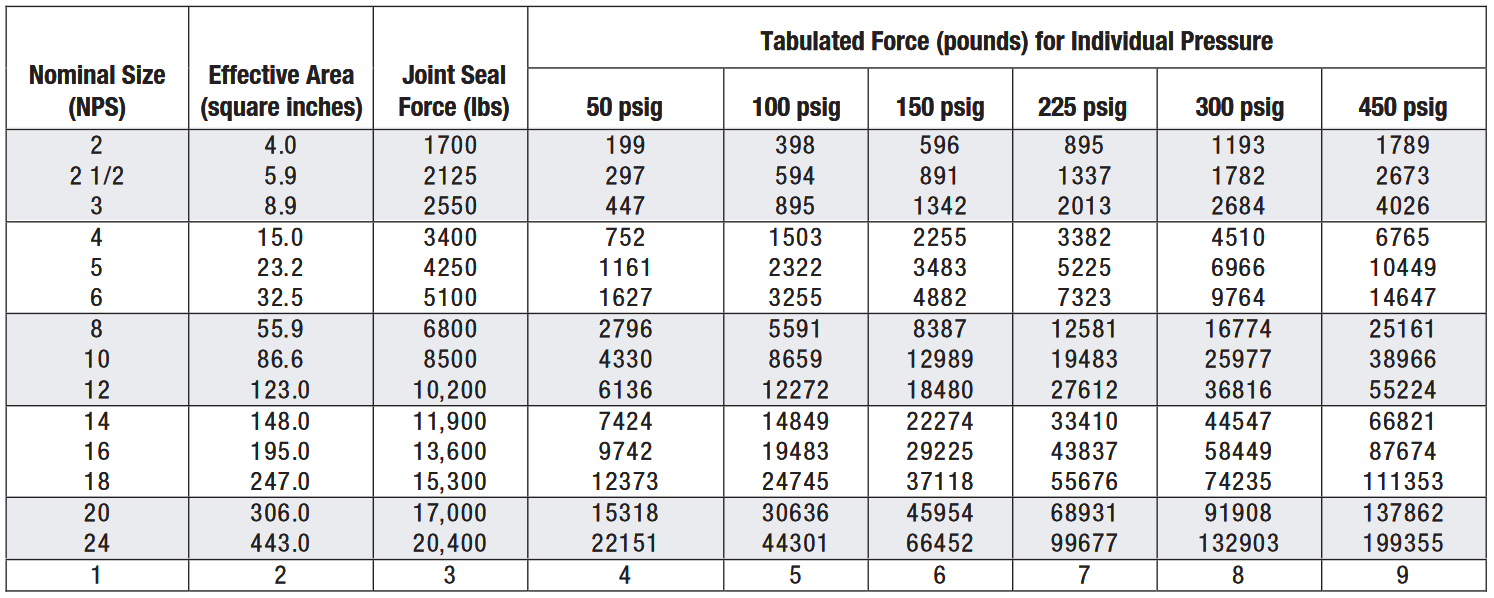

Series 6500 expansion joints are designed for installations where the principal movement is axial. Standard single configurations are designed for 4″, 8″ and 12″ of axial compression (pipe expansion) and 1″, 1.5″ and 2″ extension respectively. Dual configurations are designed for 8″, 16″ and 24″ of axial compression and 2″, 3″ and 4″ extension respectively. If the primary movement is extension (pipe contraction), the expansion joint can be preset at the factory. The piping system must include anchors to react the force produced by pressure thrust and the friction force, to react the weight of the pipe and media, and guides to ensure that the pipe alignment is maintained.

Design Data

Note:

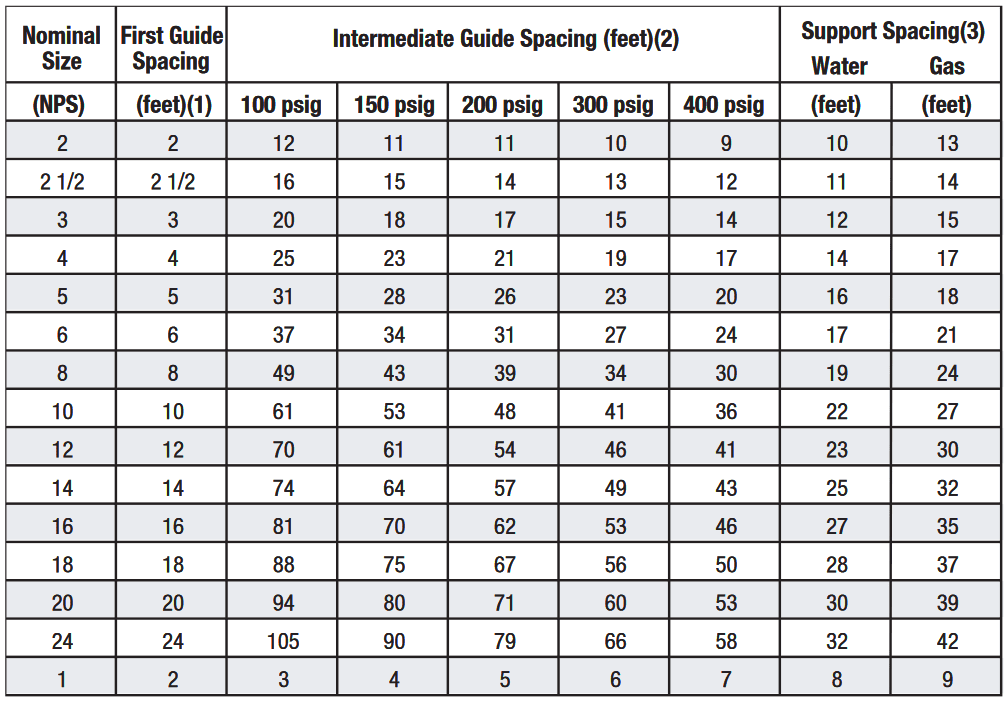

(1) Distance measured is from the face of the expansion joint. Recommend distance 10–14 pipe diameters. Tabulated values are based on 12 pipe diameters.

(2) Tabulated values are based on Hyspan Series 6500 friction forces and standard weight carbon steel pipe. Distances are center to center. Pressures are design values. Guide spacing has been calculated for test pressure (1.5 X design.)

(3) Tabulated values are the maximum recommended—source ASME 31.1 Power Piping Code.

Note:

(1) Refer to Table 3 for pressure thrust and friction force.

(2) For Type 6505 and 6506 the travel stated is the total. Travel each side of the anchor base is 1/2 of the tabulated value.

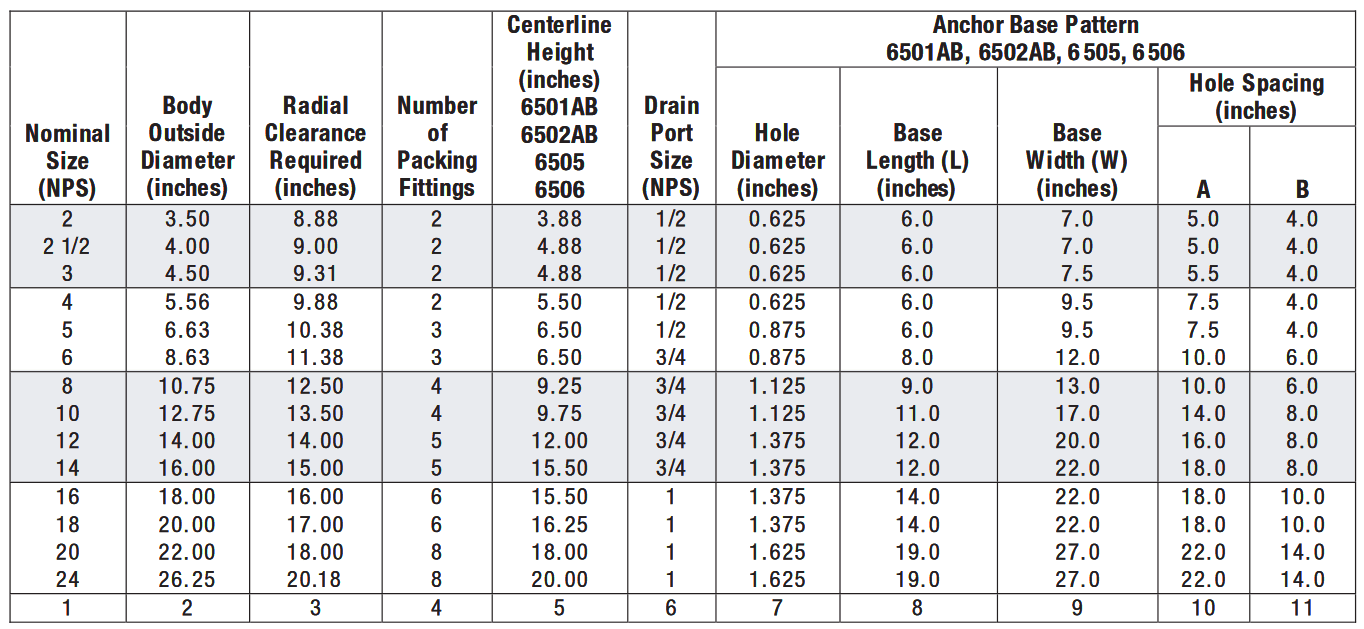

(3) Refer to Table 4 for the housing outside diameter, packer clearance, drain port size, centerline height for anchor base models, and anchor base details

Note:

(1) Refer to Table 3 for pressure thrust and friction force.

(2) For Type 6505 and 6506 the travel stated is the total. Travel each side of the anchor base is 1/2 of the tabulated value.

(3) Refer to Table 4 for the housing outside diameter, packer clearance, drain port size, centerline height for anchor base models, and anchor base details

Ordering Information

- Refer to Tables 5 through 8 to select the configuration and service conditions required for your application.

- If the travel required is unknown see the method of calculation on Page 5.

Example

2″ NPS

Single Expansion Joint

Steel pipe weld ends

150 psig at 500°F maximum

4.0″ axial travel maximum

6502-131-4

6502: Type specification, single weld end

131: Size & pressure designation, 2″ NPS, 150 PSIG

4: Axial travel, 4.0″ compression, 1.0″ extension

Single expansion joints, 6501 and 6502, ordered with anchor based are identified as 6501AB and 6502AB. Anchor bases are standard on dual anchor base joints, 6505 and 6506, and do not require the AB suffix.

Optional features must be specified by a written description accompanying the part number. Options that are available include:

- Higher rated pressure and temperature

- Alternate materials

- Vent or instrumentation ports

- Factory preset of overall length

- Service outlets (size and orientation must be specified)

- Grooved end attachments

- 1/4 Turn valve on each injector fitting

- Threaded adjusting rods for field preset

Hyspan products are available from Sales Representatives and Distributors, or they can be purchased direct from the factory. The minimum factory order for open account customers, COD shipments, or bank card sales is $100.00 (USD). All major credit or debit cards are accepted. The minimum order for new account applicants is $100.00. Our Confidential Credit Application can be downloaded and forwarded to Hyspan for processing. All orders are subject to the following Terms and Conditions, and the above warranty applies to all material. Please read these documents.

![]() Confidential Credit Application (13.9 KB), can be completed on line.

Confidential Credit Application (13.9 KB), can be completed on line.