Benefits

- Lowest cost expansion joint products

- Lowest pressure drop if there are no changes in direction

- No change in direction required

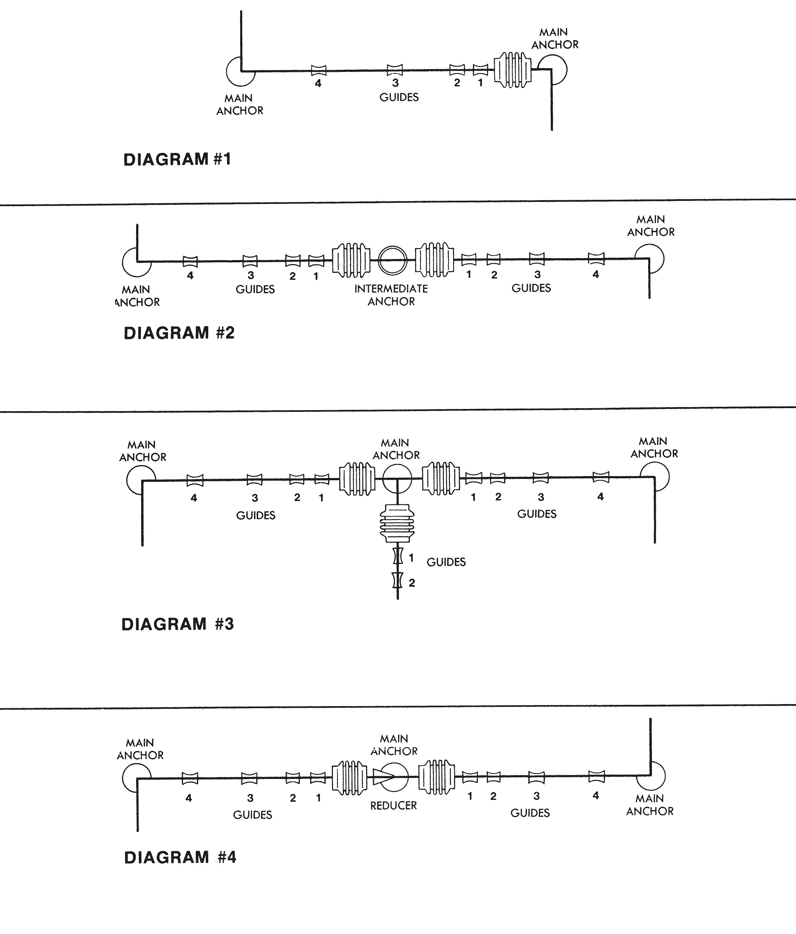

Expansion joints in axial pipe systems move parallel to the pipe centerline. This common configuration includes straight piping with main anchors at the end of a run to react pressure force, spring force, alignment guide friction force, and support friction force.

DIAGRAM #1

Single expansion joint used to absorb axial pipe line movement and positioned as shown between two main anchors.

DIAGRAM #2

Two Expansion Joints in longer pipe run than that shown in Diagram #1. Intermediate anchor between main anchors form individual expanding and contracting sections. Expansion Joints are installed between intermediate and main anchors.

DIAGRAM #3

Expansion joints, guides and anchors, absorbing movement in piping layout with branch connection. Anchor at the junction serves as a main anchor and is designed to resist thrust from the branch line expansion joint.

DIAGRAM #4

Expansion joints, guides and anchors, absorbing axial pipe line movement in a piping system having a reducer. One main anchor at reducer (center of diagram) is designed to resist the differential in the thrust of both expansion joints.