Benefits

- Lowest system install cost

- Lowest system forces and risk

- Minimum alignment guide requirements

Expansion joints in lateral (Offset®) pipe systems move perpendicular to the pipe centerline. This configuration includes at least one 90-degree elbow and an additional pipe. Only intermediate anchors are required for spring forces, alignment guide force, and support friction force.

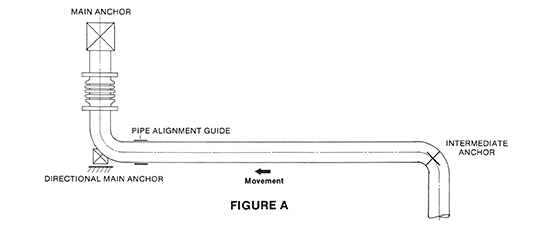

Figure A shows an arrangement in which the expansion joint is installed in a short piping leg and the expansion is absorbed as lateral deflection. The longer piping leg is free of compressive pressure loading and requires only an intermediate anchor and directional guiding. The functions of the directional main anchor and the pip guides are combined in a single device.

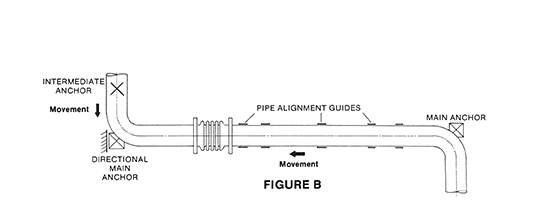

A single expansion joint can absorb combined axial and lateral movements. The expansion joint is located at one end of the long piping run with main anchors at each end. Guides must be properly spaced to provide for both movement control and protection of the piping against buckling.

The anchor at the left (Figure B) is a directional main anchor with absorbs the main load in the direction of the expansion joint axis and permits the growth of the short piping leg to act upon the expansion joint as lateral deflection. Because the main anchor loading exists only in the piping segment containing the expansion joint, the anchor at the end of the shorter piping leg is an intermediate anchor.

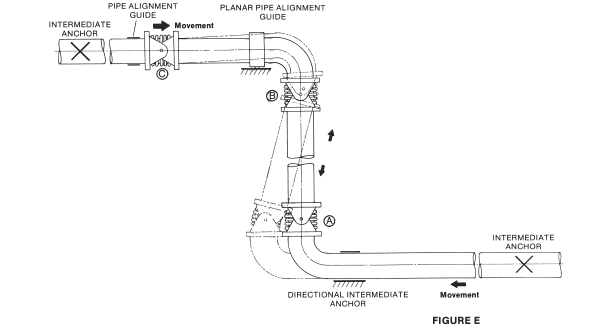

This illustration (Figure E) shows the application of the hinged expansion joint. It is possible to eliminate expansion joint C if the horizontal piping runs are sufficiently long enough to absorb motion by bending. The amount of bending deflection can be controlled by properly designed guides and supports.

The compact size of hinged expansion joints facilitates installation and provides additional rigidity an strength to the piping system. Their ability to transmit loads minimizes forces on piping and anchors. Consideration must be given to conveyant and piping weights as well as wind loads when designing hinged expansion joints.

When large amounts of single plane movement are encountered, it may be absorbed through the use of hinged expansion joints. These units permit angular movement only and cannot be extended or compressed.