Benefits

- No change in direction required

- Lowest pressure drop if no changes in direction

Expansion joints in Multi Axis pipe systems move in at least two planes. The motions may be parallel and perpendicular to a pipe centerline, or in two perpendicular plane. Solutions include a single expansion joint for all motions or two expansion joints with a 90-degree elbow.

The Pressure Balanced Expansion Joint

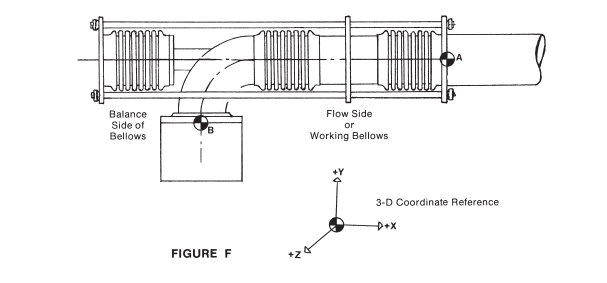

The pressure balanced expansion joint (Figure F) is used most frequently in applications similar to those shown for the single expansion joint, but where pressure thrust loading upon piping or equipment is considered excessive or objectionable.

The pressure balanced bellows creates an equal and opposite force to the working bellows. The usual arrangement is to have a balance and a flow side or working bellows, separated by an elbowed min-section.

The bellows elements are connected by tie rods which allow them to balance pressure thrust forces. When pressure is applied, both bellows react simultaneously and the tie rods absorb the thrust forces, thus keeping loads off mating equipment. Movements X, Y, and Z imposed on the pressure balance unit are usually references to the applicable working points, by a 3-dimensional coordinates system. Related forces and movements are determined from this information.

Single expansion joint solutions will induce pressure force and require main anchors

Two expansion joints with a 90-degree elbow solutions do not induce pressure force and require only intermediate (non-pressure thrust) anchors.