![]()

Since the company’s beginning in 1968, Hyspan has specialized in the fabrication of metal bellows and hoses, and in the fabrication and development of assemblies that incorporate these components. Hyspan engineers are experienced in product design, manufacturing engineering, and process engineering to support this development.

Because of the specialized nature of these products, it is frequently necessary to design and fabricate the forming machines, tools and fixtures, and test apparatus to support product development. As a result, the company’s fabrication capabilities include tool and die and machine tool fabrication in addition to bellows and hose forming, precision machining, a variety of welding and brazing processes, plate fabrication, and metal forming and rolling.

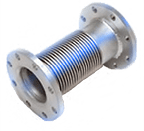

Bellows sizes range from 1” (25mm) through 20’ (6m). Complete metal bellows and hose assemblies with flanges, pipe, or tube ends are provided from 321, 304/304L, and 316/316L. Formed metal bellows are also available in AL6XN, Alloy 625, Alloy 718, B265 Grade 2 Titanium, and others.

Hyspan standard bellows are cataloged on the Series 7500 webpage. However, blank-sheet design and build-to-print are typical for the OEM industry. Replacements and reverse-engineered solutions are also available. Engineered designs can comply with the Expansion Joint Manufacturers Association (EJMA®) standards, ASTM F1120-87, ASME B31.1, ASME B31.3, or PED if required. Canadian Registration Number (CRN) is available. Our customer base is extensive, including automotive, aerospace, marine, defense, scientific, power, and industrial applications.

Welding is per ASME Section IX. NAVSEA welding is available.

Hyspan is an ISO 9001:2015 registered company with a quality system that supports requirements of the piping and boiler pressure vessel codes. These include popular ASME B31.1, ASME B31.3, and ASME Section VIII Division 1 codes. European Pressure Equipment Directive (PED) standards, with CE markings, can be supported in many applications. Canadian Registration Number (CRN) support is available.

Nondestructive testing and inspections are performed by company personnel including radiography. Quality personnel are certified to the standards of the American Society of Nondestructive Testing (ASNT). Hyspan is a member of the Expansion Joint Manufacturers Association (EJMA ®). A copy of our Hyspan EJMA ® certificate is available.