8503-8506 Steel Pipe Compensator, 3/4″ to 4″ NOM

Information at a Glance

Series

8500 Expansion Compensators

![]()

Material

Steel

Size

3/4 -4 in. / 19-100 mm

Pressure

≤200 PSI / 13 & 7 Bar

Motion

3+ in. / 75+ mm

Canadian Registration

![]()

This product is registered throughout Canada under

CRN 0D9278.59870YTNADD3

Other Products

Product Description

Series 8500 Expansion Compensators are designed for installations where the principal movement is axial. Standard designs are 3/4” through 4” for steel pipe and copper tube with 2” or 3”axial compression. Service conditions are 200 psig to 500°F. Steel pipe ends are threaded, welded, grooved or flanged. Copper tube ends are male or female sweat connections.

Technology & Advantages

The bellows element of Series 8500 Expansion Compensators is completely enclosed and externally pressurized which prevents damage to the bellows and eliminates pressure instability. The pipe or tube telescopes into the compensator providing a smooth full bore, and isolates the bellows from the flow. Series 8500 products are available from stock and have a Three year full replacement warranty.

Type 8503 Cut-a-way

Common Applications

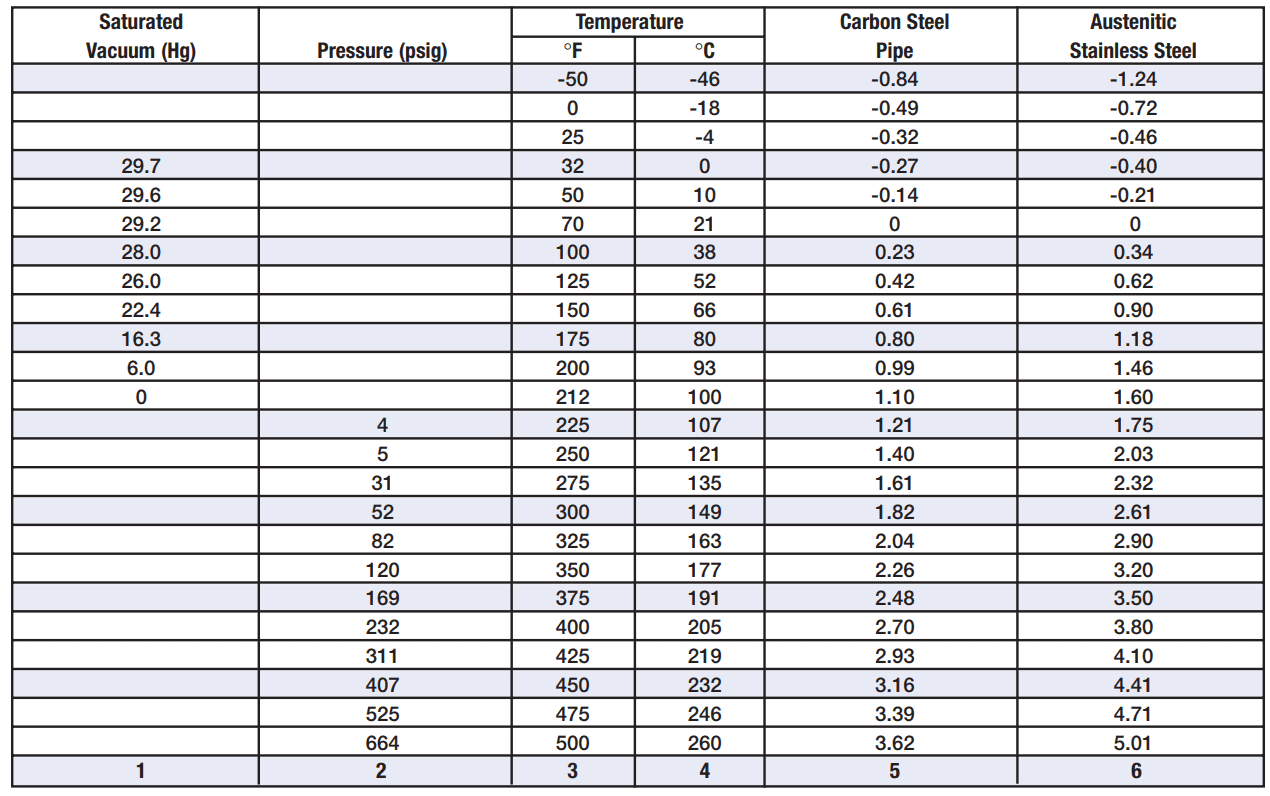

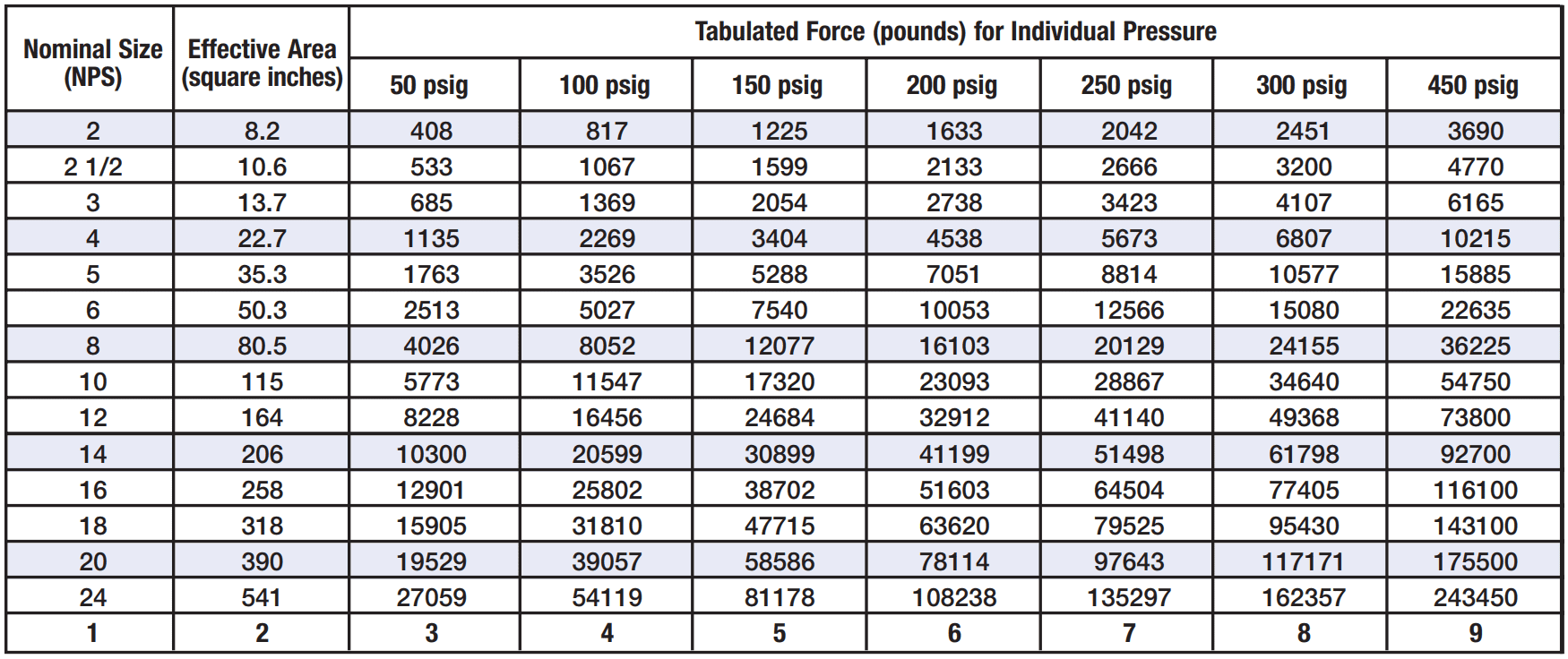

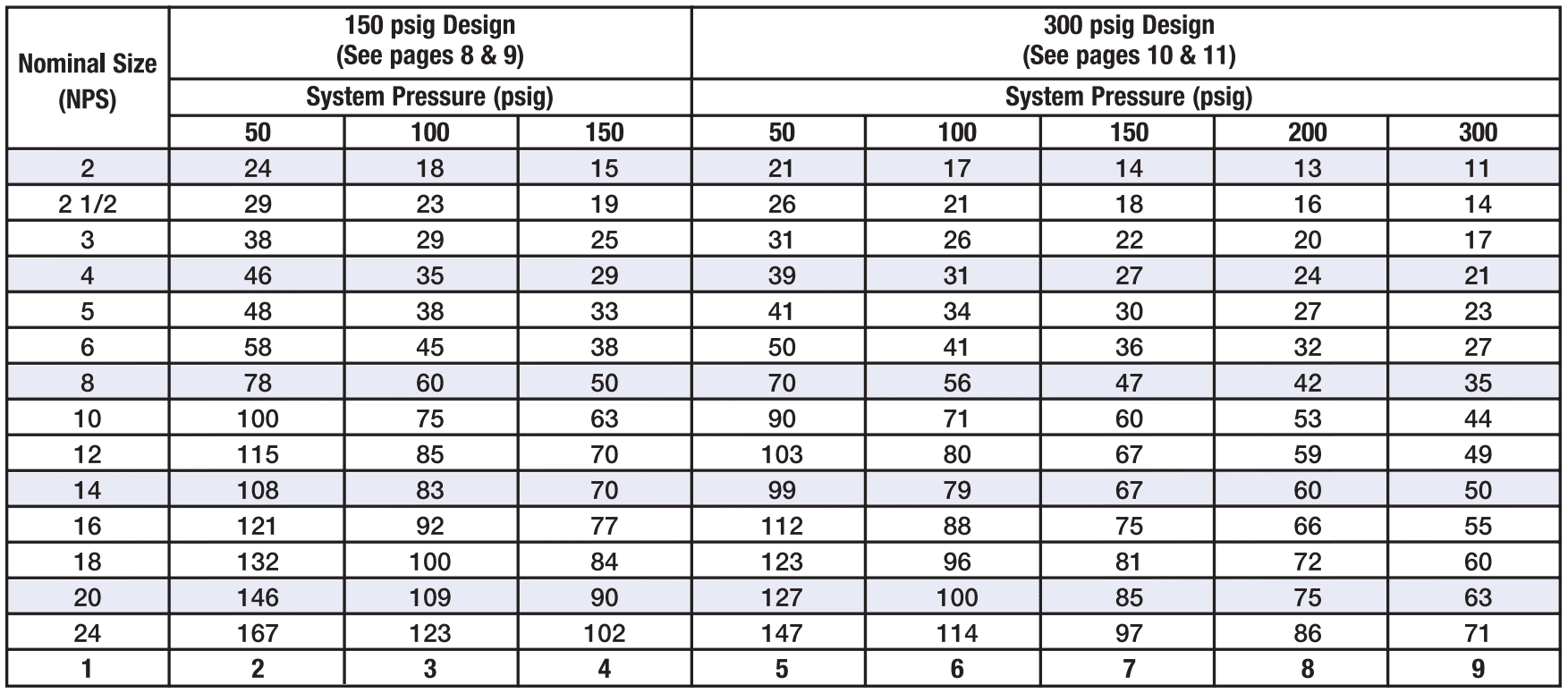

Series 8500 Expansion Compensators are designed for installations where the principal movement is axial. Standard joints are designed for 2” or 3” axial compression (pipe expansion) and 0.5” extension. If the primary movement is extension (pipe contraction) the compensator can be preset at the factory. The piping system must include anchors to react the force produced by pressure thrust and the bellows spring constant, supports to react the weight of the pipe and media, and guides to ensure that the pipe alignment is maintained.

Refer to Table 2 for the intermediate guide spacing in the center of runs.

Design Data

Ordering Information

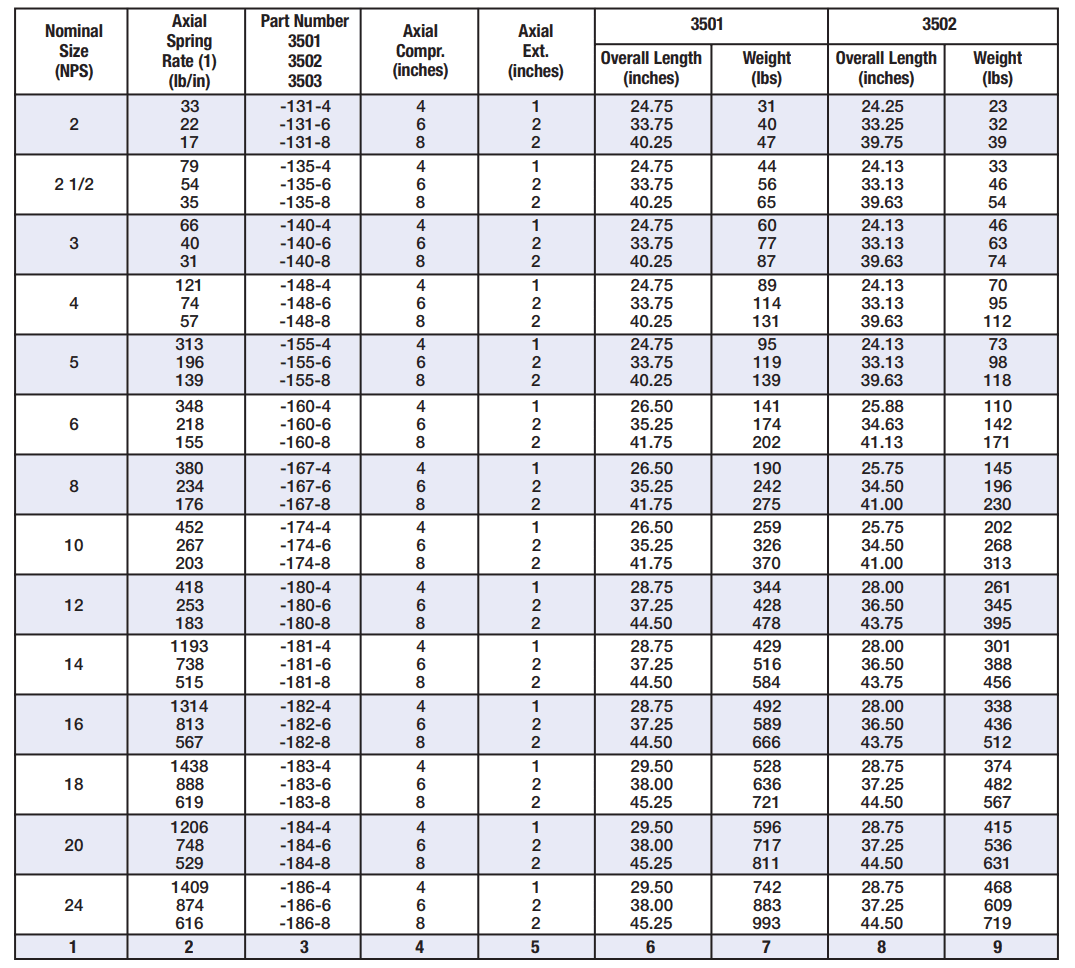

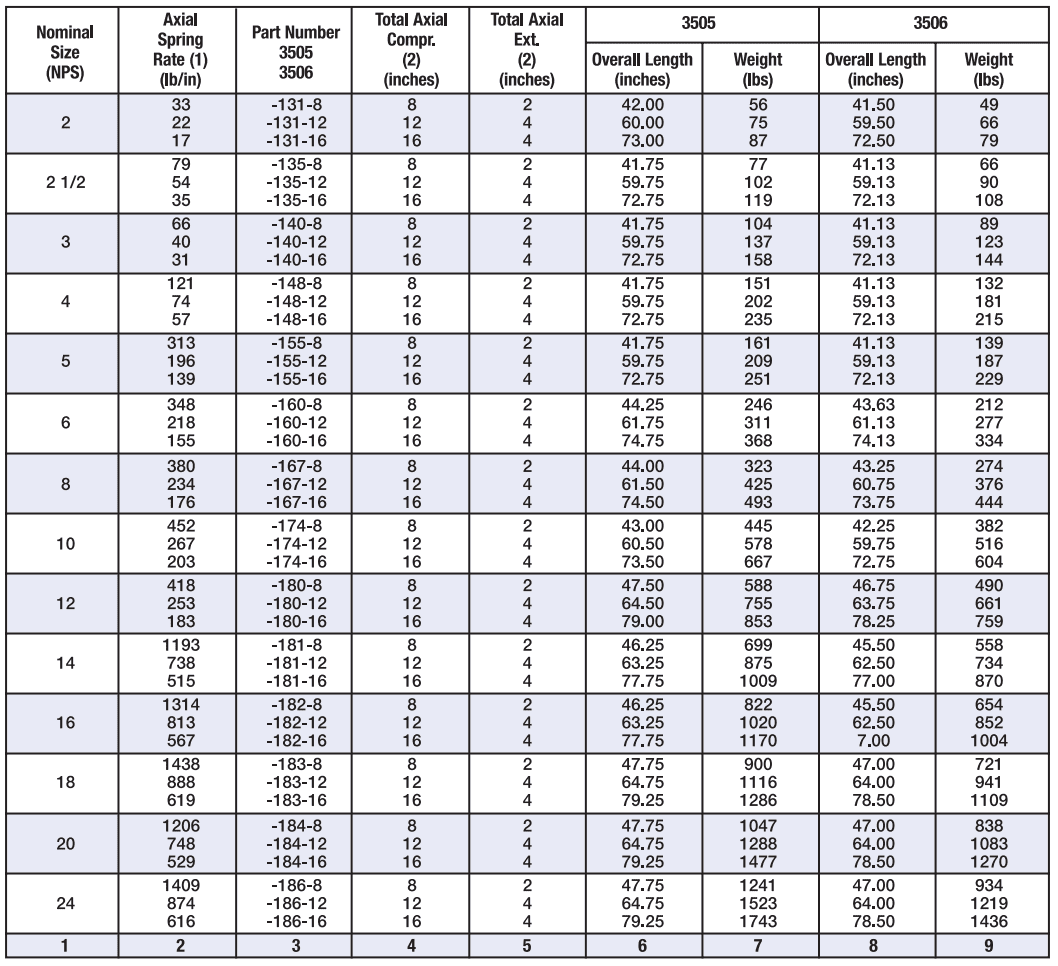

- Refer to Tables 5 & 6 on Page 5 for the steel pipe or copper tube end configuration required for your application.

- If the travel required is unknown, see the method of calculation shown on this page.

Example

Threaded steel pipe ends 8503-231-2

200 psig at 500°F maximum

2.0″ axial travel maximum Axial travel, 2.0″ compression, 0.5″ extension

2″ NPS

8503-231-2

8503: Model specification, male pipe thread both ends, steel pipe, steel housing and guides

131: Size designation, 2″ NPS, (Table 5)

4: Axial travel, 2.0″ compression, 0.5″ extension

- Model 8503, 8504, 8505 and 8506 are available with all stainless steel construction for low temperature or highly corrosive service. Must be specified by written description.

- All Series 8500 compensators are available with multiple Alloy 625 bellows for highly corrosive media. Must be specified by written description.

Hyspan products are available from Sales Representatives and Distributors, or they can be purchased direct from the factory. The minimum factory order for open account customers, COD shipments, or bank card sales is $100.00 (USD). All major credit or debit cards are accepted. The minimum order for new account applicants is $100.00. Our Confidential Credit Application can be downloaded and forwarded to Hyspan for processing. All orders are subject to the following Terms and Conditions, and the above warranty applies to all material. Please read these documents.

![]() Confidential Credit Application (13.9 KB), can be completed on line.

Confidential Credit Application (13.9 KB), can be completed on line.